Water-Cooling with Hardline Tubing Guide: Brass and Carbon Fibre

February 1, 2018 | 14:00

Companies: #alphacool

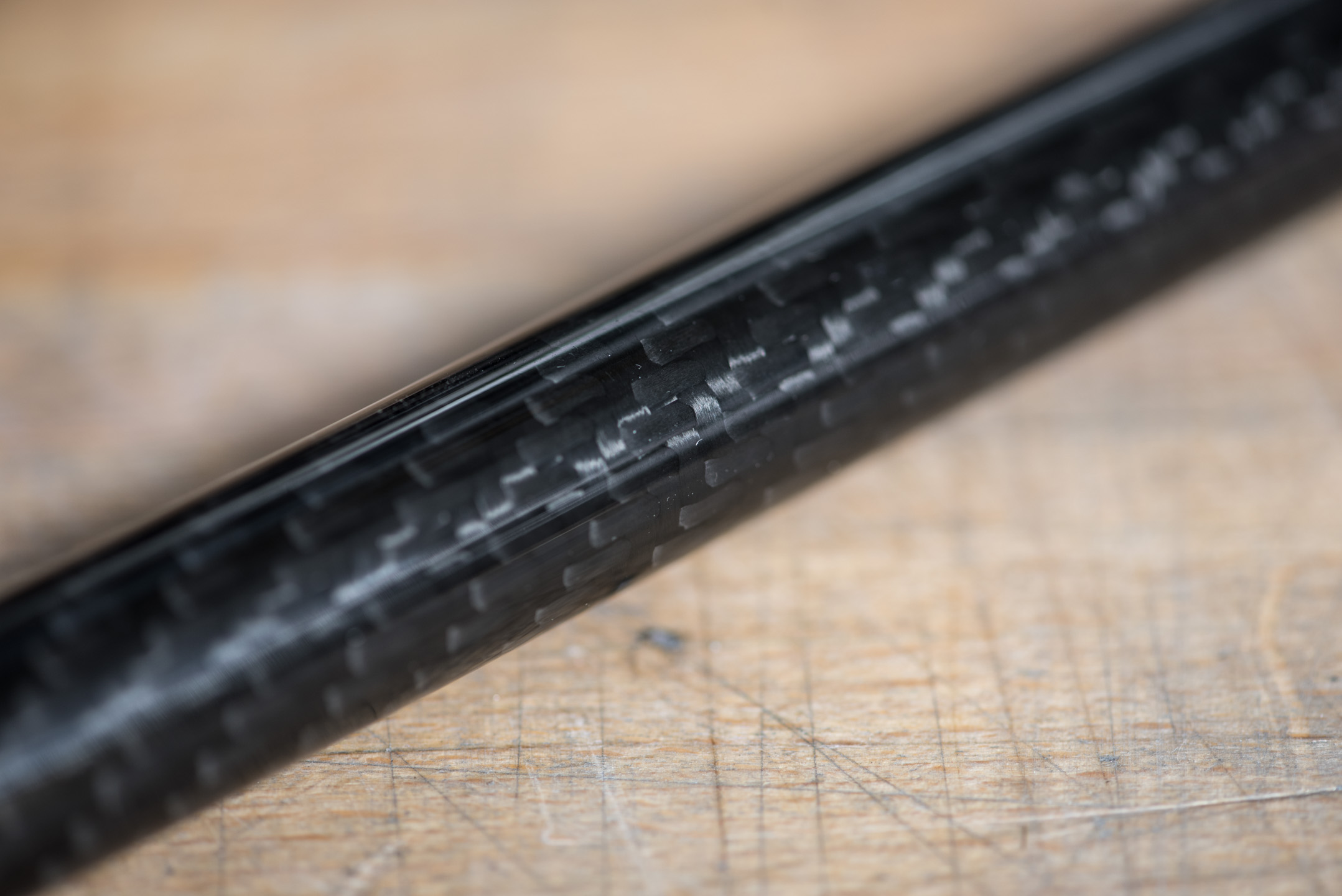

Hardline Tubing: Carbon Fibre

Moving onto carbon fibre, we're shifting away from water-cooling manufacturer territory and into "tubes that fit". Alphacool does have a line of carbon tubes, but they're purely in 12mm Outer Diameter and are the matte finish variety, meaning no visible weave or pattern. As such, if you're looking to go with a twill or plain weave variety, you'll have to shop around for local composites suppliers or stray further afield and order from Aliexpress etc.

I've chosen some 16/14mm (16mm Outside Diameter, 14mm Inside Diameter) tubing that uses the classic twill weave pattern popularised in motorsport (and used on vinyl the world over). This particular tube has a very glossy finish and, in my opinion, looks fantastic. Real carbon reflects the light in very interesting ways thanks to being a heavily anisotropic material, so using the real stuff when paired with case lighting can be rather special.

Safety and the Method

Those who have worked with carbon fibre before will be well-versed in how dangerous this stuff can be. Both the fibres themselves and the resin are nasty, so I would recommend kitting yourself out to handle it properly. Using a mask, gloves, and safety glasses is definitely a good idea if you're going to be cutting a fair bit of the stuff. Some will say it's pointless, but I'd rather err on the side of caution. The gloves, at least, will protect your hands from the fine dust and also a bit against splinters, which for the record are extremely painful. My hands react quite badly to dust of most kinds, so when cutting/sanding carbon I always wear nitrile work gloves. They won't stop major splinters, as those are really sharp and cut through, but they offer a level of defence without losing much dexterity.

Naturally, a tubing cutter won't work here, so you'll want to use a saw. Again, I like to use a coping saw, although a hacksaw would work very well too thanks to the fine teeth. It is possible, of course, to use a power tool such as reciprocating saw or a jigsaw, although they can sometimes rip the final cuts of the tube worse than by hand if you're not careful.

A good tactic if going by hand is to keep the pressure light and let the saw do all the work; this will help prevent the blade from catching on the fibres. You can also 'wet-cut' to help reduce dust and lubricate the blade. I was left with a very small lip on mine, which is fine, as we'll be sanding down the ends like with all other rigid tubes. If using a vice or clamp, use light pressure, as you don't want to crush the tubing. My twill weave tube is likely very pressure-resistant thanks to the construction method (however, I didn't test this) but matte, extruded kinds can crush quite easily, as the fibres run parallel along the length of the tube.

Carbon sands very, very easily. I do a quick wet sand at 320- and 500-grit to get wonderful, smooth edges. These aren't just important for the fittings this time; the smooth ends will also protect your hands when you're installing the tubes into the water-cooling system later.

PSA: CHECK YOUR MEASUREMENTS

Measuring the tube simply provides some peace of mind and ensures you won't unexpectedly spring a leak one day. If your 16mm tube turns out to be 5/8" for instance, and rather than 15.875mm is actually 15.75 (since that original size will have tolerances too), it may explain why it's not sitting snugly in your fittings.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.